The characteristics and advantages and disadvantages of various couplings

Coupling is an important device used in many large-scale transmission equipment. The operation of this component directly affects the working efficiency and service life of the equipment. Therefore, considerable attention should be given to not only selecting the appropriate device, but also paying attention to the usual maintenance. Maintenance and timely replacement if necessary.

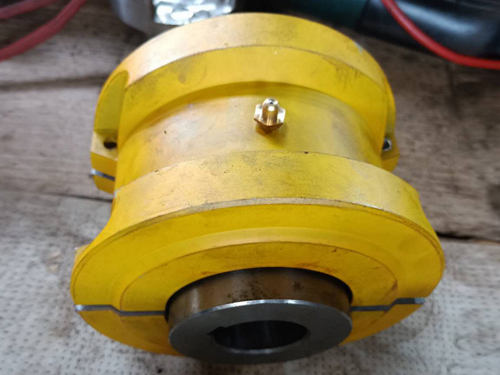

The couplings we usually see now mainly have tooth-shaped embedded ones, which are sealed and have high requirements on the quality of lubricating oil, and also have high requirements on the flow rate, so they must be checked and relubricated from time to time; although It is more troublesome, but the distance it can transmit is larger, so it is a large-scale equipmentFirst choice.If the shrapnel type is used, although it is also sealed, it is not demanding and can be adjusted according to the actual situation.The slider type is also commonly used, which can be directly filled with oil for lubrication, or filled with oil-soaked felt.

Although there are various types of couplings, they should be selected according to the time of the machine when choosing, so as to ensure normal installation and operation.The most basic principle is that the external dimensions of the selected components must not be too large, must be able to be accommodated in the installation space, and need to leave a certain amount of room for observation and maintenance at any time, and it is more convenient when it needs to be disassembled.It should be noted that if it is a large-scale equipment, it is more troublesome to adjust, so you should choose more wear-resistant and longer-life components as much as possible, which can delay the maintenance cycle and reduce the trouble and cost of replacement and debugging.Nowadays, many companies have begun to use diaphragm components with better performance, which not only have a long service life, but are also easier to maintain, which can effectively improve production efficiency.