Diaphragm coupling

Diaphragm couplings are widely used in shaft transmission of various mechanical devices, such as water pumps (especially high-power and chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining Machinery, metallurgical machinery, aviation (helicopter), naval high-speed power transmission systems, steam turbines, piston-type power mechanical transmission systems, crawler vehicles, and generator sets high-speed, high-power mechanical transmission systems, which are applied to high-speed transmission after dynamic balance Shafting has become more common.

The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. It is a high-performance flexible coupling with metal strong components. It does not require lubrication, has a compact structure, and has a long service life. Rotation, not affected by temperature and oil pollution, has the characteristics of acid and alkali resistance, and is suitable for shafting transmission in high temperature, high speed, and corrosive medium conditions.

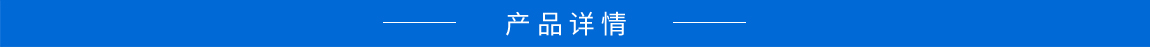

The diaphragm coupling is composed of several groups of diaphragms (stainless steel thin plates) that are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rods and different shapes. Sliced.

The main characteristics of the diaphragm coupling

1. The ability to compensate for the misalignment of the two axes is strong. Compared with the gear coupling, the angular displacement can be doubled, the reaction force is small during radial displacement, the flexibility is large, and some axial, radial and angular displacements are allowed .

2. It has obvious effect, no noise and no wear.

3. It is suitable for working in high temperature (-80+300) and harsh environment, and can operate under shock and vibration conditions.

4. Transmission, up to 99.86%.Especially suitable for medium, high speed and high power transmission.

5. Simple structure, light weight, small size, convenient assembly and disassembly.It can be assembled and disassembled without moving the machine (refer to the type with intermediate shaft), and no lubrication is required.

6. It can accurately transmit the speed without slip, and can be used for mechanical transmission.

The correct choice of diaphragm coupling:

1. The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.Some manufacturers provide two diaphragms, and others provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve.

2. The characteristic of diaphragm coupling is a bit like a bellows coupling. In fact, the way the coupling transmits torque is similar.The diaphragm itself is very thin, so it is easy to bend when the relative displacement load is generated, so it can withstand up to 1.5 degrees of deviation, while generating a lower bearing load in the servo system.

3. Diaphragm couplings are often used in servo systems. Diaphragms have good torque rigidity, but are slightly inferior to bellows couplings.

4. On the other hand, the diaphragm coupling is very delicate, and it can be easily damaged if it is misused or not installed correctly during use.Therefore, the deviation is very large within the tolerance range of the normal operation of the coupling.

5. Adjust the model according to the shaft diameter:

The initially selected coupling dimensions of the bearing coupling, that is, the shaft hole diameter d and the shaft hole length L, should meet the requirements of the shaft diameters of the driving and driven ends, otherwise the coupling specifications must be adjusted according to the shaft diameter d.

It is a common phenomenon that the shaft diameters of the driving and driven ends are different. When the torque and speed are the same, and the shaft diameters of the driving and driven ends are different, the coupling model should be selected according to the larger shaft diameter.In the newly designed transmission system, the seven shaft hole types specified in GBT3852 should be selected, and the J1 shaft hole type is recommended to improve versatility and interchangeability. The shaft hole length is in accordance with the i-bearing coupling product standard. .

江苏Diaphragm coupling Shandong diaphragm coupling

-

How to analyze the cause of damage to the elastic pin coupling?And the classification of elastic pin couplingsElastic pin coupling, generally elastic pin coupling, nylon rod pin coupling, the former is...Take you to understand commonly used elastic couplingsCommonly used elastic couplings are divided into two types of elastic sleeve pin couplings and elastic pin couplings...

-

Rigid movable couplingTypes of rigid removable couplings (couplings without elastic elements): Oldham...Classification and performance of couplingsCouplings are also called couplings.Used to firmly connect the driving shaft and the driven shaft in different mechanisms...

-

The characteristics and maintenance methods of gear couplingGear coupling is a kind of removable rigid coupling.It uses internal and external tooth meshing to realize the torque rotation and movement transmission between the two halves of the coupling. It is suitable for the transmission shaft system connecting two concentric shafts, and has the performance of relatively compensating the relative displacement of the two shafts.Its structure is shown in Figure XNUMX. It is composed of main parts such as inner gear ring, gear shaft sleeve and end cover. Generally, small-sized gear coupling end cover and inner gear ring can be integrated. ...The structure and application range of slider couplingThe slider coupling is also known as the metal cross slider coupling. Its slider is in the shape of a ring and is made of steel or alloy. The cross slider coupling is suitable for transmissions with low speed and large transmission torque.The slider coupling is composed of two shaft sleeves and a slider. ...