Take you to understand commonly used elastic couplings

Commonly used elastic couplings are divided into two types of elastic sleeve pin couplings and elastic pin couplings

XNUMX. Elastic sleeve pin coupling

A. Structure: The structure is similar to the flange coupling, except that the connection bolt is replaced by the cancellation with a rubber elastic sleeve;

B. Principle: Use the elastic deformation of the elastic sleeve to compensate the relative displacement of the two shafts;

C. Features: The elastic sleeve pin coupling is easy to manufacture, easy to assemble and disassemble, and has a low cost, but the elastic sleeve is easy to wear and has a short life.

D. Applicable to: two-axis connection with stable load, forward and reverse rotation or frequent start, high speed transmission of small and medium torque.

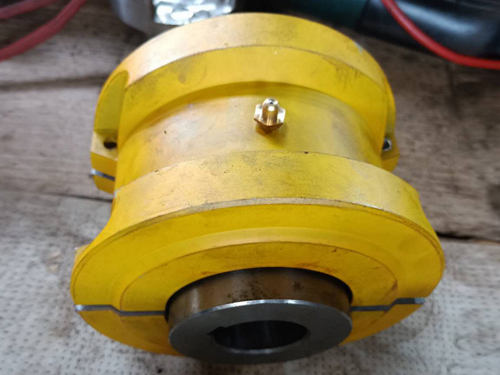

XNUMX. Elastic pin coupling

A. Structure: A number of pins made of non-metallic materials are placed in the flange holes of the two halves of the coupling to realize the connection of the two halves of the coupling; the pin material is usually nylon, and other non-metallic materials with elasticity also may.

B. Principle: Use the elastic deformation of the elastic pin to compensate the axial displacement of the two shafts;

C. Features: The elastic pin coupling can allow greater axial movement, but the amount of compensation for radial displacement and deflection angle displacement is not large.Its structure is simple, easy to manufacture and easy to maintain.

D. Suitable for: light load occasions