Softening deformation treatment and fixing treatment method of pin coupling

The pin coupling has a simple and reasonable structure, convenient maintenance, symmetrical and interchangeable on both sides, long life, allowing large axial movement, and has the properties of buffering, shock absorption, and wear resistance.The pin coupling is a pin made of a number of elastic materials such as polyurethane, placed in the flange hole of the two halves of the coupling, and the two halves of the coupling are connected through the pin. The coupling has a simple structure. It is easy to manufacture, and it is convenient to repair and replace the elastic element, without moving the two halves of the coupling.

The material of the elastic element (column pin) is generally nylon, which has the ability to slightly compensate the deviation of the two axes. However, the elastic part is sheared during operation, and the working reliability is extremely poor. It is only suitable for the medium-speed transmission shaft system with very low requirements. It is suitable for working conditions that require high working reliability.It is suitable for all kinds of mechanical transmission linking two coaxial transmission shafts, usually used for high and low speed movements with frequent movement.The pin coupling screw fixation is to lock the fixed shaft with a 90° gap between two positioning screws. In the traditional fixing method, because the front end of the screw contacts the shaft, it may cause damage to the shaft or difficulty in disassembly.

The pin coupling clamping screw is fixed by using the tightening force of the hexagon socket bolt to shrink the slit and clamp the shaft tightly.This method is convenient to fix and disassemble, and will not cause damage to the shaft, so it is a very common fixing method.Keyway type fixation is suitable for high-torque transmission. In order to prevent axial sliding, it is usually used together with set screw fixation and clamping screw fixation. D-shaped hole is usually fixed, if the motor shaft is D-shaped, if the positioning screw cannot be fixed, the coupling hole can be processed into a d-shaped hole corresponding to the size of the motor shaft and fixed with the positioning screw , Don’t worry about slipping.

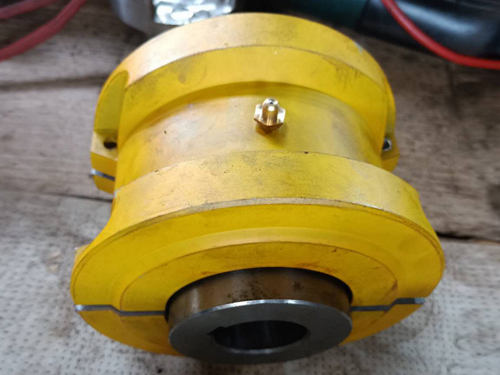

The pin coupling expansion sleeve is fixed by tightening the four positioning screws on the end of the coupling to compress the account cover. It is suitable for the connection and fixing of some stepping motors and servo motors with large torque, such as expansion sleeve diaphragms. Couplings, plum blossom couplings with expansion sleeves, bellows couplings with expansion sleeves, etc.The heating temperature of the coupling cushioning elastomer should not exceed 100 degrees Celsius. If it is higher than 100 degrees Celsius, the coupling elastic body will be heated and softened.Under the action of external force during operation, the elastic element is bent, twisted, elliptical or other abnormal changes; during operation, the parts of the coupling are overheated, squeezed, etc., resulting in changes in the mechanical properties of the surface and causing damage .