Flexible coupling

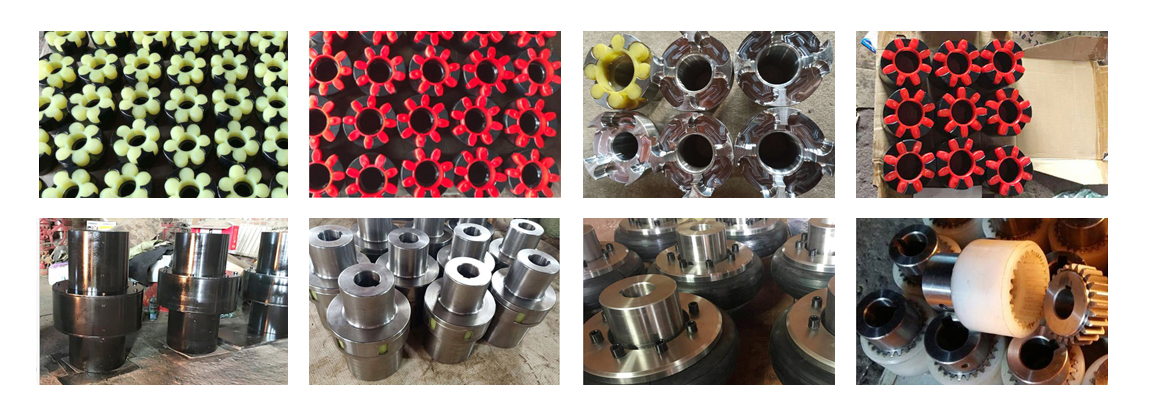

The elastic coupling is an integrally formed metal elastic body, usually cut from a metal round bar. The commonly used materials are aluminum alloy, stainless steel, and engineering plastics, which are suitable for various deviations and torque transmission.

The elastic coupling contains an elastic compound of pre-compressed rubber to provide additional strength and extend service life.The coupling can accommodate all types of deviations.The wheel hub is made of aluminum alloy, which is both lightweight and durable.Among them, the rubber component is mainly used to make the power transmission smooth and quiet, thereby protecting the driving force and driving the machine.

The installation is simple, because the rubber part is a split insert, it can be plug-in installation after the axis is aligned.

The elastic coupling uses parallel or spiral groove system to adapt to various deviations and transmit torque.Flexible couplings usually have good performance and price advantages. In many practical applications of stepping and servo systems, flexible couplings are the main product of choice.The one-piece design enables the flexible coupling to achieve the advantages of zero torque transmission and no maintenance.The elastic coupling mainly has the following two basic series: spiral groove type and parallel groove type.

特点

(1) One-piece metal elastomer;

(2) Zero rotation and synchronous operation;

(3) Elastic action compensates radial, angular and axial deviations;

(4) High torque rigidity and sensitivity;

(5) The clockwise and counterclockwise rotation characteristics are the same;

(6) Maintenance-free, oil-resistant and resistant;

(7) There are aluminum alloy and stainless steel materials for selection;

(8) There are two main fixing methods: top wire and clamping.

江苏Elastic coupling Shandong elastic coupling

-

Coupling terminology◆Rated torque: refers to the torque capacity that the coupling can continuously transmit.Changes during operation have been considered...Coupling three table alignmentS1= ±(Axial difference of counter wheel (absolute value of opening)×distance from foot 1 to measuring point) ÷ measuring point diameter±circumferential radial...

-

How to analyze the cause of damage to the elastic pin coupling?And the classification of elastic pin couplingsElastic pin coupling, generally elastic pin coupling, nylon rod pin coupling, the former is...Take you to understand commonly used elastic couplingsCommonly used elastic couplings are divided into two types of elastic sleeve pin couplings and elastic pin couplings...

-

Rigid movable couplingTypes of rigid removable couplings (couplings without elastic elements): Oldham couplings, universal couplings and drum gear couplings...Classification and performance of couplingsCouplings are also called couplings.A mechanical component used to firmly connect the driving shaft and the driven shaft in different mechanisms to rotate together and transmit motion and torque.Sometimes it is also used to connect shafts and other parts (such as gears, pulleys, etc.).It is often composed of two halves, which are connected by a key or tight fit, respectively, and fastened to the ends of the two shafts, and then the two halves are connected in some way.The coupling can also compensate for the offset between the two shafts due to inaccurate manufacturing and installation, deformation or thermal expansion during work, etc. (including axial offset, radial offset...