Coupling three table alignment

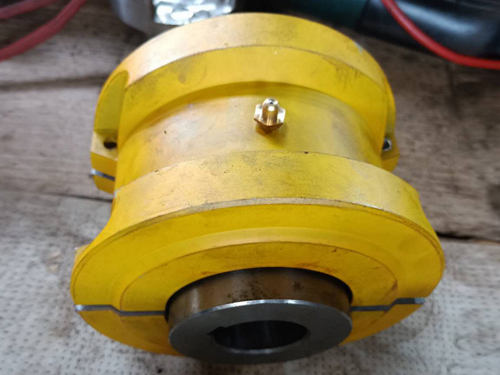

Coupling alignment is also called concentric.After the pump and motor are installed,最后One task is to find the concentricity of the pump and the motor, that is, make the axis of the pump and the prime mover on the same straight line, so that it does not cause vibration during operation.When the newly installed pump is aligned, the radial and axial errors of the coupling may appear in the following four situations:

method one:

General pumps (water pumps, small oil pumps) can be roughly measured with a flat ruler or feeler gauge, but for most equipment, precise measurement is required, and a dial indicator is used for measurement.Generally, the level of the pump has been determined, and the counter-wheel of the pump is used as a benchmark to measure and adjust the motor counter-wheel to ensure the alignment of the motor and the pump.

注:a1、a2、a3、a4 表示径向间隙,S1、S2、S3、S4 表示轴向间隙测量时先测出百分表在0º时的径向间隙a1 和轴向间隙S1,然后分别测出90º、180º、270º的径向与轴向间隙,并分别记录于上图所示的圆内与圆外。测量回到0º时,必须与原始读数一致,否则要查找原因,一般由轴窜动或地脚螺栓松动所致。最后测量数据还须符合以下条件,才表示计算正确。a1+a3=a2+a4S1+S3=S2+S4

Method two:

Aligning the two pump tables:

Mount the dial indicator to the pump end, adjust the dial indicator to zero, rotate the counter wheel one circle, and get a value every 90 degrees.最后The dial indicator must return to zero when it returns to its starting position. The sum of the left and right readings should be equal to the sum of the upper and lower values.Then analyze the relative spatial position of the two axes according to the readings, and make appropriate adjustments according to the deviation value.First adjust the left and right deviation of the coupling to the allowable value, and then adjust the height to within the standard.

Correction formula:

S1= ±(Axial difference of opposite wheel (open mouthabsoluteValue)×distance from foot 1 to measuring point) ÷ measuring point diameter±circumferential radial interpolation (difference) value/2

S2= ±(Difference in axial direction of opposite wheel×distance from foot 2 to measuring point) ÷ diameter of measuring point±circumferential and radial interpolation (difference) value/2

the firstA ±: If the opposite wheel is the upper mouth, take the "+" sign; if it is the lower mouth, then the "-" sign can be understood as the upper-to-lower plate

The second ±: when the motor is low, take "+"; when the motor is high, take "-". It can be understood that the dial table from top to bottom is positive writing is negative writing negative

If S1 is positive (the upper mouth is open and the motor is low), it means that the gasket should be cushioned, and the number of S1 is the thickness of the gasket to be cushioned.

Another: The diameter of the measuring point is the rotating diameter of the measuring point, not the diameter of the coupling.Adjusting left and right is similar.

Method three, add cushion method

加减垫子计算方法(a3-a1)xL1/D+(s3-s1)/2 (a3-a1)x(L1+L2)/D+(S3-S1)/2 其中a表示轴向表读数 D表示靠背轮直径 L1表示靠背轮到电机前脚距离 L2表示电机前脚到后脚的距离, S表示径向表的读数 这得出的结果就是你电机要加在前脚和后脚的垫子数量。

It is good for double-meter to align, but the axial displacement is sometimes difficult to grasp.The novice may not be able to do it for a long time by luck, but the master can do it in ten minutes with experience!the bestAdd an axial watch at 180°.The so-called three-meter alignment!