How to analyze the cause of damage to the elastic pin coupling?And the classification of elastic pin couplings

Elastic pin couplings are generally elastic pin couplings, nylon rod pin couplings, the former are connected by several screws, and the nut ends of the screws are equipped with elastic washers.The latter uses nylon rods. The two half-sections are drilled as large as holes, and the nylon rods are inserted. The outside is covered with a baffle, a pin coupling, and a pin coupling. The half couplings are connected by N nylon rods.Can play a role in compensation.

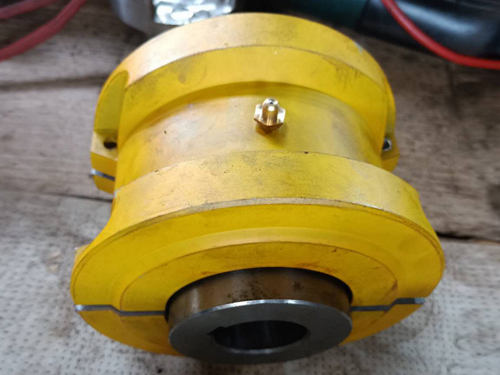

Pin couplings, commonly used models include elastic sleeve pin coupling (TL), elastic pin coupling (HL), and elastic pin gear coupling (LZ).

The basic parameters and main dimensions of the ZL-type elastic pin gear coupling are made of a number of non-metallic pins, placed in the mating hole between the two halves of the coupling and the inner surface of the outer ring, and transmitted through the pin The torque realizes the coupling of the two halves of the coupling.

LT type (formerly TL type) elastic sleeve pin coupling. The elastic sleeve pin coupling uses a pin with an elastic sleeve (rubber material) on one end and is installed in the flange holes of the two halves of the coupling. Realize the connection of the two halves of the coupling.The elastic sleeve pin coupling used to be a relatively widely used coupling in my country. It was formulated as a standard for the Ministry of Machinery in the late 20s. The JB50-08 elastic ring pin coupling was a relatively early part of my country. Standard coupling.

HL型-弹性柱销联轴器已列为**标准GB5014-85,适用于各种机械联接两同轴线的传动轴,通常用于动频繁的高低速运动。工作温度为-20 ~+80℃;传递公称扭矩为40~20000N.m。弹性柱销联轴器具有较大结构简单、合理,维修方便、两面对称可互换,寿命长,允许较大的轴向窜动,具有缓冲、、等性能。

How to analyze the cause of damage to the elastic pin coupling?The elastic pin coupling is used to connect the elastic pin coupling of the master-slave shafting of power machinery.Circumferentially aligned elastic elements 1 are connected to the master-slave hubs 4 and 5 of the coupling, and the helical ring-shaped elastic body of the elastic pin coupling formed by the multi-strand steel wire stranded wire fixedly connected by the metal splint constitutes the coupling The annular free deformation space between the master and slave hubs of the coupling, the coupling master and slave hubs constitute elastic displacement compensation features in the axial, radial, and axial inclination directions through the annular free deformation space.It is suitable for shafting connection of various types of power devices driven by marine main and auxiliary engines, internal combustion engines, diesel couplings, electric motors and hydraulic motors (especially with single-layer or double-layer elastic vibration isolation foundation).

The torsional vibration test is carried out on the ship. From the test results, the torsional vibration characteristics of the coupling are very small relative to the allowable value, but the coupling is continuously damaged. In addition to eliminating its own quality problems and torsional vibration, what other factors are there in general? Can cause damage to the coupling?

1. Principle: The main elastic drum gear coupling of the high elastic coupling is a torsionally loaded rubber component. The rubber component can be designed in a single row or multiple rows. Each rubber component has a variety of standard stiffnesses to choose from. The drum gear coupling can meet the rigidity requirements determined by the torsional vibration calculation in a relatively range.The main purpose of using highly elastic couplings in marine power systems is to transmit power and torque, compensate for radial, axial and angular alignment errors, and compensate for oscillations of rotational momentum.Adjust the natural vibration frequency of the system.Highly elastic pin coupling has the characteristics of light weight, easy installation, large displacement compensation in all directions, large damping, strong vibration absorption and frequency modulation capabilities, etc., which can better protect the main coupling, gear box and shaft system.

2. Reason analysis:

1) The elastic shock absorber of the main machine sinks, causing the shafting to be misaligned, and additional torque is generated!This possibility is great for new ships.

2) Elastic pin coupling rubber drum gear coupling heat and fracture accident; matching problem: only the various equipment in the shaft system, such as diesel coupling, high elastic elastic pin coupling, gear box, shaft The other components and propellers of the system are well designed and complement each other and support each other, and they all improve the design level, so that the ship designed in this way is a ship in the sense.