The diaphragm coupling cannot be opened when the machine is running normally

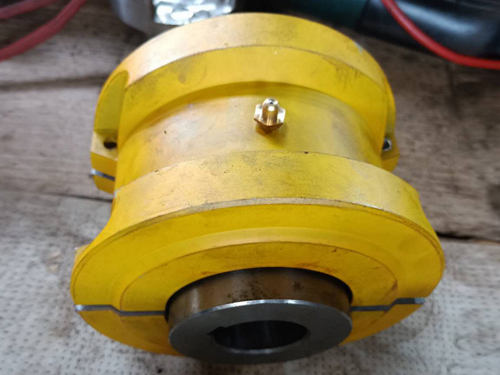

The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.The diaphragm coupling is very delicate and can be easily damaged if it is misused or improperly installed in use.Diaphragm couplingOften used in servo systems, the diaphragm has good torque rigidity, but it is slightly inferior to the bellows coupling.

The diaphragm in the middle of the diaphragm coupling is made of high-grade stainless steel, which can ensure that the diaphragm is not only high in strength, long-lasting, and durable, but also suitable for most working conditions.At the same time, the surface of the diaphragm is covered with a coating with a low coefficient of friction to reduce friction and improve its resistance to contact wear.The diaphragm coupling adopts a unique 6-hole, 8-hole or 10-hole diaphragm group. With the increase of the number of holes, the torque that the coupling can transmit is higher and the rigidity is stronger, but the corresponding displacement deviation can be accommodated. small.The elastic diaphragm coupling compensates the relative displacement of the two shafts connected by the elastic deformation of the diaphragm. It is a high-performance flexible coupling with metal elastic elements. It does not require lubrication, has a compact structure, high strength and long service life. , No rotation gap, not affected by temperature and oil pollution, with acid resistance, alkali resistance, and corrosion resistance. It is suitable for high temperature, high speed, and corrosive medium shafting. It is widely used in shafting of various mechanical devices. Transmission, such as water pumps (especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters), high-speed naval power The transmission system, after being dynamically balanced, is commonly used in high-speed transmission shaft systems.

The elastic diaphragm coupling cannot be disengaged at will during the normal operation of the machine, and it must be shut down to disengage.This kind of coupling is mainly a component that connects two drive shafts and transmits torque to it, but sometimes it is also used as an overload safety device.The structure of the elastic diaphragm coupling is that the diaphragm group is fixed to the two halves of the coupling with bolts. The bolt holes are divided into 4 holes, 6 holes, 8 holes, 10 holes, and 12 holes.The form of the diaphragm is divided into continuous polygonal ring, circular ring, separated connecting rod shape, spoke shape, formed diaphragm and waved diaphragm.Centrifugal stress due to inertia during high-speed rotation.Assuming that the bolt and the coupling diaphragm are of the same material, the respective masses can be calculated. According to the position and the spiral angle, the centrifugal force can be calculated and acted on the total center of mass.

The centrifugal inertial force of high-speed machinery is very important in the stress calculation of the structure. The centrifugal inertial force can be loaded according to the radial force, and the direction is radially outward, and the radial displacement, circumferential displacement and axial displacement of the middle bolt hole are fixed. , There is no other load around.Due to the error of the axial installation, the diaphragm is bent and deformed along the axial direction.The displacement is loaded in the axial direction of the middle bolt hole, and the radial displacement and the axial displacement are fixed.The two middle holes at both ends are used to impose constraints, and the middle hole is used to bear the load.In this way, it is treated as a statically determinate simply supported mechanism.