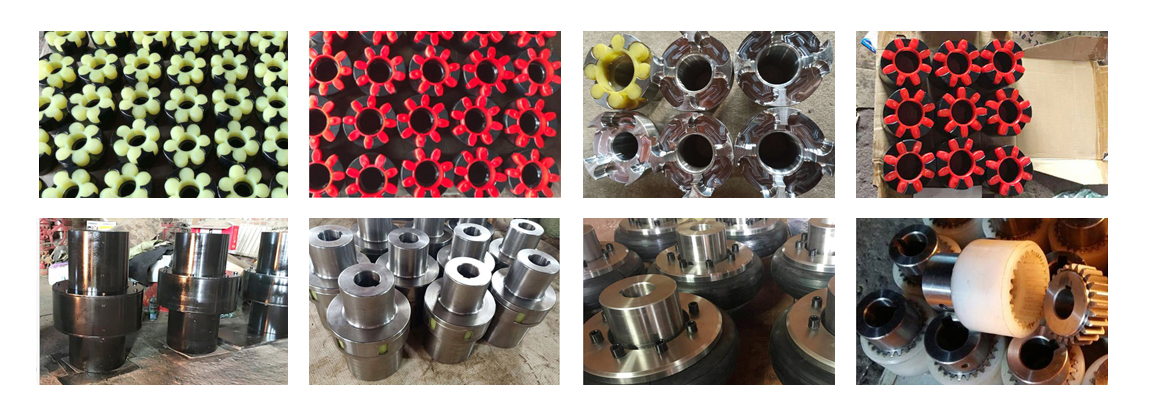

DJM type expansion sleeve diaphragm coupling

Main features of DJM type expansion sleeve diaphragm coupling:

1. The allowable range of eccentricity is large and can be flexibly applied to various transmission systems.

2. Disassembly and assembly are of high importance for assembly.

3. Good environmental adaptability, can operate at high temperature.

4. Simple structure and light weight.

5. No maintenance is required, and faults can be checked with the naked eye when shutting down.

6. No lubrication, no noise and wear.There are no sliding, friction, or rotating parts, which can reduce energy loss.

7. High transmission accuracy.High sex and long life.

DJM type expansion sleeve coupling elastic diaphragm coupling is widely used in shaft transmission of various mechanical devices, such as water pumps (especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery , Textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters), naval high-speed power transmission systems, steam turbines, piston-type power mechanical transmission systems, crawler vehicles, and high-speed, high-power mechanical transmission systems of generator sets, After being dynamically balanced, it is relatively common to apply to high-speed transmission shafting.

The main dimensions and basic parameters of the DJM expansion sleeve coupling single-type diaphragm coupling:

| specification | Aperture d mm | D mm | L mm | A mm | B mm | Weight kg | Permissible speed rpm | Nominal torque Nm | Allowable compensation | |

| Angular (°) | Axial mm | |||||||||

| 01 | 8-22 | 68 | 90 | 6.1 | 26 | 0.85 | 20000 | 33 | 1 | ± 0.8 |

| 02 | 10-32 | 81 | 95 | 6.6 | 26 | 1.2 | 20000 | 90 | 1 | ± 1.0 |

| 03 | 10-35 | 93 | 110 | 8.4 | 29 | 1.7 | 18000 | 173 | 1 | ± 1.2 |

| 04 | 10-42 | 104 | 124 | 11.2 | 34 | 2.7 | 15000 | 245 | 1 | ± 1.4 |

| 05 | 15-50 | 126 | 152 | 11.7 | 42 | 6.5 | 13000 | 420 | 1 | ± 1.6 |

| 06 | 15-60 | 143 | 170 | 11.7 | 48 | 8.9 | 12000 | 772 | 1 | ± 1.8 |

| 07 | 20-70 | 168 | 210 | 16.8 | 58 | 15.8 | 10000 | 1270 | 1 | ± 2.5 |

江苏DJM type expansion sleeve diaphragm coupling Shandong DJM type expansion sleeve diaphragm coupling

-

Coupling terminology◆Rated torque: refers to the torque capacity that the coupling can continuously transmit.Changes during operation have been considered...Coupling three table alignmentS1= ±(Axial difference of counter wheel (absolute value of opening)×distance from foot 1 to measuring point) ÷ measuring point diameter±circumferential radial...

-

How to analyze the cause of damage to the elastic pin coupling?And the classification of elastic pin couplingsElastic pin coupling, generally elastic pin coupling, nylon rod pin coupling, the former is...Take you to understand commonly used elastic couplingsCommonly used elastic couplings are divided into two types of elastic sleeve pin couplings and elastic pin couplings...

-

Rigid movable couplingTypes of rigid removable couplings (couplings without elastic elements): Oldham couplings, universal couplings and drum gear couplings...Classification and performance of couplingsCouplings are also called couplings.A mechanical component used to firmly connect the driving shaft and the driven shaft in different mechanisms to rotate together and transmit motion and torque.Sometimes it is also used to connect shafts and other parts (such as gears, pulleys, etc.).It is often composed of two halves, which are connected by a key or tight fit, respectively, and fastened to the ends of the two shafts, and then the two halves are connected in some way.The coupling can also compensate for the offset between the two shafts due to inaccurate manufacturing and installation, deformation or thermal expansion during work, etc. (including axial offset, radial offset...