The correct choice of diaphragm coupling

The correct choice of diaphragm coupling:

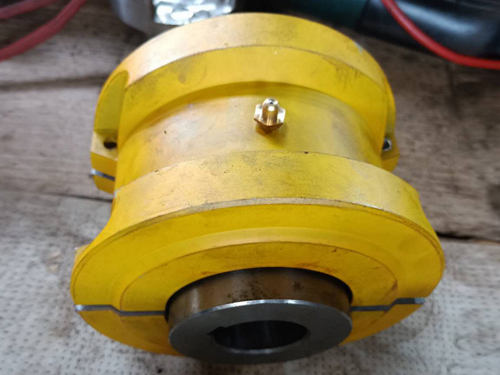

1. The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.Some manufacturers provide two diaphragms, and some provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve.

2. The characteristic of diaphragm coupling is a bit like a bellows coupling. In fact, the way the coupling transmits torque is similar.The diaphragm itself is very thin, so it is easy to bend when the relative displacement load is generated, so it can withstand up to 1.5 degrees of deviation, while generating a lower bearing load in the servo system.

3. Diaphragm couplings are often used in servo systems. Diaphragms have good torque rigidity, but are slightly inferior to bellows couplings.

4. On the other hand, the diaphragm coupling is very delicate, and it can be easily damaged if it is misused during use or not installed correctly.Therefore, the deviation is very large within the tolerance range of the normal operation of the coupling.

5. Adjust the model according to the shaft diameter:

(1) The initially selected coupling size of the bearing coupling, that is, the shaft hole diameter d and the shaft hole length L, should meet the requirements of the shaft diameter of the driving and driven ends, otherwise the coupling specifications must be adjusted according to the shaft diameter d .

(2) It is a common phenomenon that the shaft diameters of the main and driven ends are different. When the torque and speed are the same, and the shaft diameters of the main and driven ends are different, the coupling model should be selected according to the larger shaft diameter.In the newly designed transmission system, the seven shaft hole types specified in GBT3852 should be selected, and the J1 shaft hole type is recommended to improve versatility and interchangeability. The shaft hole length is in accordance with the i-bearing coupling product standard. .