What is a diaphragm coupling?

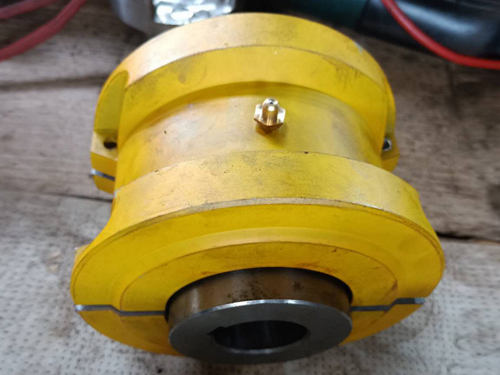

Diaphragm coupling is a coupling that uses thin springs to connect with the two halves of the coupling by bolts or other coupling methods to realize the elastic connection of the two shafts.The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.The difference between the single diaphragm coupling and the double diaphragm coupling is the ability to handle various deviations. In view of the complex bending of the diaphragm, the single diaphragm coupling is not suitable for eccentricity.The double diaphragm coupling can bend in different directions at the same time to compensate for eccentricity.

The diaphragm coupling is mainly composed of several groups of diaphragms that are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is made up of several pieces. The diaphragms are divided into connecting rod type and different shape of the whole piece type.The diaphragm coupling compensates for the relative displacement of the two shafts connected by the elastic deformation of the diaphragm. It is a high-performance flexible coupling with strong metal components. It does not require lubrication, has a compact structure, and has a long service life. Rotating, not affected by temperature and oil pollution, has the characteristics of acid and alkali resistance, suitable for high temperature, high speed, and corrosive medium shafting transmission, which is widely used in shaft transmission of various mechanical devices, such as: water pump (especially High-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation helicopters, naval high-speed power transmission systems, steam turbines, piston power Mechanical transmission systems, crawler vehicles, and high-speed, high-power mechanical transmission systems of generator sets have been commonly applied to high-speed transmission shafts after being dynamically balanced.

Compared with the gear coupling, the diaphragm coupling has no relative sliding, no lubrication, sealing, no noise, basically no maintenance, easy to manufacture, and can partially replace the gear coupling.Diaphragm couplings are already very common in the industry. The machinery industry standard has been formulated in our country and has been revised as a new industry standard: JB/T9147-1999 (instead of ZB/TJ19022-90).