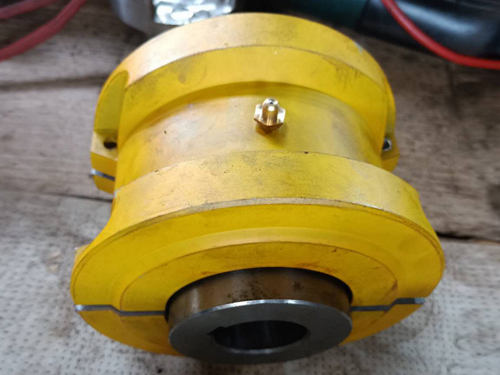

Features of diaphragm coupling and installation precautions

Diaphragm coupling is a general-purpose mechanical component, and it is a high-performance flexible coupling with metal elastic elements.It is suitable for shafting transmission in high temperature, high speed, and corrosive medium working conditions, and is widely used for shafting transmission of various mechanical devices, such as water pumps, high-speed power transmission systems for ships, etc.

Features of diaphragm coupling:

1. The ability to compensate for the misalignment of the two axes is strong. Compared with the gear coupling, the angular displacement can be doubled, the reaction force is small during radial displacement, the flexibility is large, and some axial, radial and angular displacements are allowed .

2. It has obvious effect, no noise and no wear.

3. It is suitable for working in high temperature (-80+300) and harsh environment, and can move under shock and vibration conditions.

4. The transmission can reach 99%, which is especially suitable for medium and high-speed high-power transmission.

5. Simple structure, light weight, small size, convenient assembly and disassembly.It can be assembled and disassembled without moving the machine (refer to the type with intermediate shaft), and no lubrication is required.

6. It can accurately transmit the speed without slip, and can be used for mechanical transmission.

Precautions for installation of diaphragm coupling:

1. The product of the diaphragm coupling has edges, and it may cause injury during installation. It is recommended to wear labor protection products such as thick gloves.

2. When the shaft center deviation exceeds the allowable value during installation, the coupling may be deformed, resulting in damage or shortened service life.

3. The allowable axis deviation of the diaphragm coupling includes radial, angular and axial deviations.When installing, please adjust the axis deviation within the allowable range of the corresponding product catalog.

4. When multiple deviations appear at the same time, the corresponding allowable value should be halved.

5. In order to prolong the service life of the coupling, it is recommended to set the axis deviation within 1/3 of the allowable value.

6. Tighten the screws after inserting the mounting shaft, otherwise the coupling will be deformed.When tightening the screws, please use a torque wrench, do not use screws other than the accessories for installation.

7. If an abnormal sound occurs during operation, please stop the operation immediately and check the installation accuracy and screw loosening.It is recommended to apply adhesive on the outer surface of the screw after installation and commissioning to increase the protection performance.

8. After the installation is completed, please install a protective cover and other devices around the coupling.

Next:What is a diaphragm coupling?