How to distinguish the type and specification of tire coupling and troubleshooting

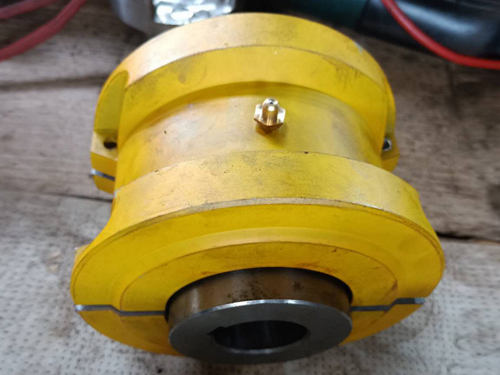

Types and specifications of tire couplings:

The main types of tire couplings are: UL tire coupling, LLB tire coupling, LLA tire coupling, DL polygonal rubber coupling, LAK saddle block elastic coupling, etc. UL type, LLB type, and LLA type are several models that are more commonly used.Below we will focus on the characteristics of these couplings: UL tire coupling specifications are mainly UL1-18, nominal torque: 10-25000, allowable speed: 5000-800, shaft hole diameter: 11 -180mm, shaft hole length: 22-302mm, weight: 0.7-818, material: 45# round steel, cast steel, forged steel. UL tire coupling has good cushioning performance, which solves the cushioning effect that ordinary couplings cannot achieve.

LLB type tire coupling

LLB type tire coupling specifications: LLB1-13 type; tire body model: LTB1-13, standard number (JBT10541-2005) original standard (JBZQ4018-85) material cast steel, cast iron and 45# round steel, other materials by our factory Can also be customized, nominal torque: 10-20000 allowable speed: 5000-1000 shaft hole diameter: 6-200mm shaft hole length: 16-382mm, quality: 0.4-340. LLB tire couplings are mostly used in metallurgical equipment, so they are also called tire couplings for metallurgical equipment. The tire coupling for LLB metallurgical equipment is a highly elastic coupling with good cushioning and inter-axis offset compensation performance. It is suitable for wet, dusty, shock, vibration, positive and negative changes and starting. Frequent working conditions and easy to disassemble and assemble.

LLA tire coupling

LLA Tire Coupling for Metallurgical Equipment Specification: LA1-11 Nominal Torque: 10-20000 Permissible Speed: 5000-800 Shaft Hole Diameter: 5-180 Shaft Hole Length: 14-302 Weight: 0.35-373kg Material: Cast Iron Cast steel, suitable for damp, dusty, shock, vibration, changeable forward and reverse and frequent starting working conditions, and easy to disassemble, without lubrication, and durable

UL type tire coupling

Among the three types of couplings, UL type tire couplings are commonly used. The tire bodies of the three tire couplings are different. The tire bodies of the UL type and LLB type tire couplings are not open. , The tire body of the LLA tire coupling is open. Under the same model, the LLB tire body is thicker than the UL tire body. The tire body of the tire coupling adopts high-quality rubber, and the rubber is distributed with nylon threads. Nylon cloth, so the tire body, has the characteristics of elasticity and long life, which is not available in ordinary tire bodies.

Introduction to advantages and disadvantages analysis

Analysis of the advantages and disadvantages of LLB tire couplings: tire couplings are divided into two major categories: convex and concave. The convex is divided into three types: integral with skeleton, integral without bone and radial incision.Their common feature is that the tire ring is bolted to connect the two halves of the coupling to realize the connection of the two shafts.The inner side of the tire ring is bonded to the steel frame by a vulcanization method, and the bolt holes on the frame are welded with nuts.When assembling, bolts are used to connect the flanges of the two coupling halves. The friction force generated between the tire and the flange end faces by tightening the bolts is used to transmit torque. The torsional shear deformation of the tire ring occurs when the tire ring is working, so the tire coupling It has high elasticity, the ability to compensate the relative displacement of the two shafts is large, and it has good damping, and the structure is simple, does not require lubrication, and is relatively convenient for assembly and disassembly and maintenance.

The disadvantage of LLB tire coupling is that the load capacity is not high and the external dimension is large. With the increase of the relative torsion angle of the two shafts, the external shape of the tire is distorted. The additional axial force increases the bearing load and reduces the life.When the tire coupling is running at high speed, the centrifugal force of the outer edge of the tire expands outward, which will further increase the additional axial force.For this reason, measures should be taken when installing the coupling to make the direction of stress in the tire opposite to the direction of stress generated during work to offset part of the additional axial force and achieve the working conditions of the coupling and the two bearings.

Common faults and maintenance of tire couplings:

XNUMX. Use the sound of the claw coupling to judge whether there is an abnormal sound, or turn the two half couplings by hand to see if there is any large clearance in the circumferential direction. If there is, the claw rubber ring may be damaged; or Check whether the half coupling and the shaft are loose.

XNUMX. For flange couplings, when the connecting bolt holes or pin holes of the two halves of the coupling are severely worn, the holes are usually machined, and the appropriate bolts are matched, or the holes are repaired by electric welding and then reworked.

XNUMX. For the slider coupling, pay attention to the lubrication.

5. For gear couplings, check the tooth profile, use a caliper, a common normal micrometer or a template to check the tooth profile.If the tooth thickness wear exceeds 30~20% of the original tooth thickness, it should be new, and the gear coupling of the operating mechanism should be 30~XNUMX%.

XNUMX. Check that the gear coupling sealing device, retaining ring, expansion ring, spring, etc. are not damaged, aging, etc., otherwise they should be replaced in time.

XNUMX. If the shaft sleeve of the half coupling and gear coupling does not meet the requirements of the drawing or the key is loose, the shaft should be repaired in time if there is a large scratch.Generally, only the coupling or the shaft sleeve is inspected, and the shaft is not allowed to be inspected to prevent the accident of broken shaft.

XNUMX. Lubricating oil should be added to the couplings that need lubrication regularly. Slider couplings, universal couplings, chain couplings, etc. should be lubricated regularly.Our company's universal couplings are used more, especially in the packaging workshop.

Common malfunctions

XNUMX. Due to low installation accuracy, loose anchor bolts, deformation of the frame, poor lubrication, etc., the gear coupling gears are abnormally worn, resulting in gear coupling transmission vibration and increased transmission noise, which affects the normal operation of the mechanism.

XNUMX. Because the coupling bolts and coupling keys are loose or the elastic pins and holes are squeezed out, the mechanism jumps when the mechanism is started, and even the bolts are cut off, resulting in mechanical failure.

XNUMX. Poor material or overload causes the coupling to crack.

XNUMX. The coupling with lubrication device leaks or deteriorates due to damage to the oil seal.