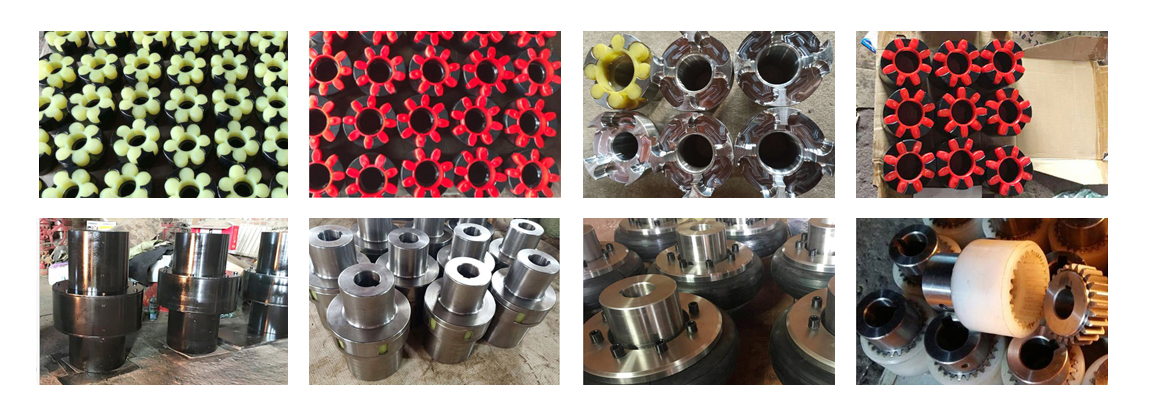

H block flexible coupling

The H-shaped elastic block coupling uses several H-shaped elastic parts, and inserts the convex blocks of the main and driven end half couplings between the H-shaped elastic parts to realize the coupling of the two halves. A shaft system.

The H-shaped elastic block coupling is widely used in the transmission shaft system connecting two coaxial lines.

The H-type elastic block coupling is simple in structure, compact in size, convenient to manufacture, low in cost, convenient in assembly and disassembly, and has the properties of compensating for the relative offset of the two shafts, damping and buffering, and is suitable for connecting two coaxial transmission shafts.

Couplings are mechanical parts used to connect two shafts (active shaft and driven shaft) in different mechanisms to rotate together to transmit torque.In high-speed and heavy-load power transmission, some couplings also have the function of buffering, damping and improving the dynamic performance of the shafting.The coupling is composed of two halves, which are respectively connected with the driving shaft and the driven shaft.The general power machine is mostly connected with the working machine by means of a coupling.

Features of H-type elastic block coupling

The metal parts of the H-type coupling are made of gray cast iron GG-25, and its elastic elements are made of synthetic rubber, which has stable torque transmission and low embrittlement effect.Due to the optimized design of the pin and elastic element, there is no wear even if the shaft alignment deviation occurs.

H-type couplings are widely used as high-speed couplings in mechanical equipment, such as pump drive systems or engine drive systems, or as low-speed large torque couplings for connecting gearboxes and drive equipment.

江苏H block type elastic coupling Shandong H block type elastic coupling

-

Coupling terminology◆Rated torque: refers to the torque capacity that the coupling can continuously transmit.Changes during operation have been considered...Coupling three table alignmentS1= ±(Axial difference of counter wheel (absolute value of opening)×distance from foot 1 to measuring point) ÷ measuring point diameter±circumferential radial...

-

How to analyze the cause of damage to the elastic pin coupling?And the classification of elastic pin couplingsElastic pin coupling, generally elastic pin coupling, nylon rod pin coupling, the former is...Take you to understand commonly used elastic couplingsCommonly used elastic couplings are divided into two types of elastic sleeve pin couplings and elastic pin couplings...

-

Rigid movable couplingTypes of rigid removable couplings (couplings without elastic elements): Oldham couplings, universal couplings and drum gear couplings...Classification and performance of couplingsCouplings are also called couplings.A mechanical component used to firmly connect the driving shaft and the driven shaft in different mechanisms to rotate together and transmit motion and torque.Sometimes it is also used to connect shafts and other parts (such as gears, pulleys, etc.).It is often composed of two halves, which are connected by a key or tight fit, respectively, and fastened to the ends of the two shafts, and then the two halves are connected in some way.The coupling can also compensate for the offset between the two shafts due to inaccurate manufacturing and installation, deformation or thermal expansion during work, etc. (including axial offset, radial offset...