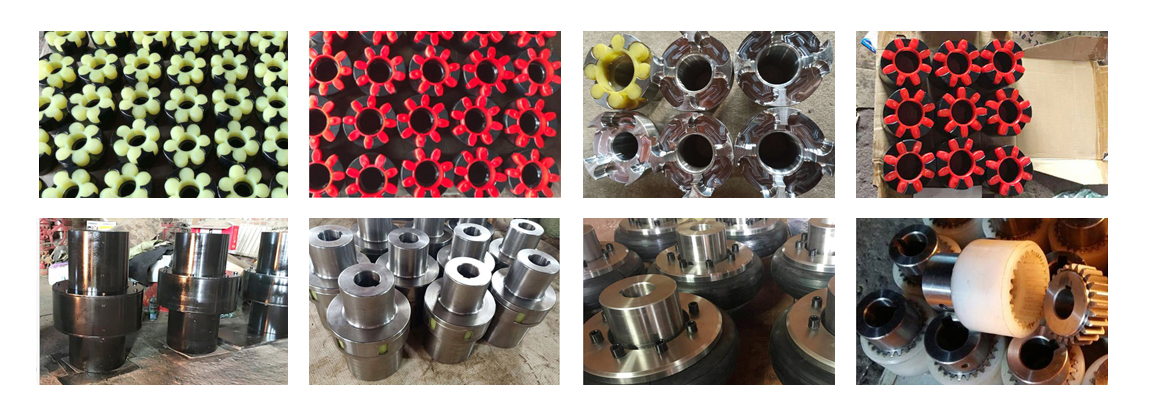

Nylon gear coupling

Nylon internal gear coupling adopts casting, cast iron HT20-40, cast steel ZG35Ⅱ, 45# steel, shaft hole and keyway are made by drawing, nylon internal gear coupling elastomer jacket can be selected according to user requirements A kind of hardness synthetic nylon, reinforced cast nylon elastomer and other materials.

Gear couplings are widely used in various machinery industries such as metallurgy, mining, lifting and transportation, petroleum and shipping due to their compact structure, large carrying capacity, wide operating speed range, and working characteristics.

Gear couplings have small radial dimensions, large carrying capacity, and are long used in shafting transmissions under low-speed and heavy-duty conditions. The dynamically balanced gear couplings can be used for high-speed transmissions, such as gas turbine shaft transmissions. .

The characteristics of nylon internal gear coupling are:

1. High load-carrying capacity, calculated by bending strength, under the same conditions, the torque transmitted by a spur gear coupling is increased by 15-30%;

2. Reasonable structure and performance. Because the tooth side is drum-shaped, the contact condition of the axis under the angle condition of the axis is reduced, thereby reducing the contact stress, and the load concentration at the tooth end of the straight tooth coupling, that is, edge extrusion , Improve work performance.

3. Good compensation performance. The tooth profile of the outer gear sleeve is drum-shaped, which increases the allowable relative deviation of the two shafts connected. The allowable inclination angle can reach 6 degrees, and 1.5°~2.5° is generally recommended.

Jiangsu nylon gear coupling Shandong nylon gear coupling

-

How to analyze the cause of damage to the elastic pin coupling?And the classification of elastic pin couplingsElastic pin coupling, generally elastic pin coupling, nylon rod pin coupling, the former is...Take you to understand commonly used elastic couplingsCommonly used elastic couplings are divided into two types of elastic sleeve pin couplings and elastic pin couplings...

-

Rigid movable couplingTypes of rigid removable couplings (couplings without elastic elements): Oldham...Classification and performance of couplingsCouplings are also called couplings.Used to firmly connect the driving shaft and the driven shaft in different mechanisms...

-

The characteristics and maintenance methods of gear couplingGear coupling is a kind of removable rigid coupling.It uses internal and external tooth meshing to realize the torque rotation and movement transmission between the two halves of the coupling. It is suitable for the transmission shaft system connecting two concentric shafts, and has the performance of relatively compensating the relative displacement of the two shafts.Its structure is shown in Figure XNUMX. It is composed of main parts such as inner gear ring, gear shaft sleeve and end cover. Generally, small-sized gear coupling end cover and inner gear ring can be integrated. ...The structure and application range of slider couplingThe slider coupling is also known as the metal cross slider coupling. Its slider is in the shape of a ring and is made of steel or alloy. The cross slider coupling is suitable for transmissions with low speed and large transmission torque.The slider coupling is composed of two shaft sleeves and a slider. ...