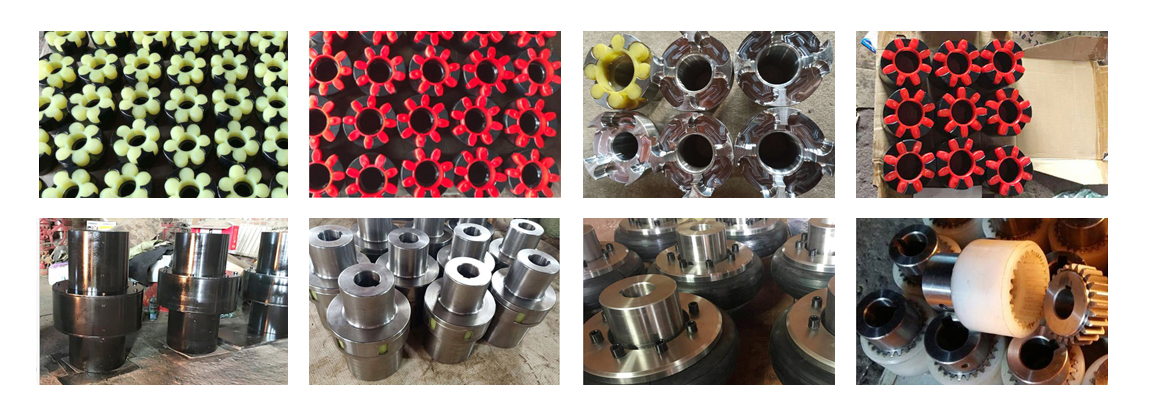

Spiral clutch coupling

The spiral groove type elastic coupling has a continuous multi-turn long slot. This type of coupling has very good elasticity and small bearing load.It can withstand various deviations and is suitable for correcting deflection and axial deviation, but its ability to deal with eccentricity is relatively poor. Because the spiral groove is bent in two different directions at the same time, a large internal pressure will be generated, resulting in Premature damage to the coupling.Although the long spiral groove coupling can easily bend under various deviations, it has the same effect on the rigidity of the coupling under the torsional load.Excessive rotation under torsional load will affect the accuracy of the coupling and weaken its overall performance.

The spiral groove type elastic coupling is a more economical choice, suitable for low torque applications, especially in the connection of encoders and other lighter instruments.

Parallel-groove flexible couplings usually have 3 to 5 slots to cope with the problem of low torque rigidity.Parallel grooves take into account that the cut grooves can be shortened without reducing the ability to withstand deviations. The short cut grooves can increase the torque rigidity of the coupling and overlap, so that it can withstand considerable torque.This performance makes it suitable for light load applications.For example, the connection of a servo motor and a ball screw.However, this kind of performance will increase the bearing load as the slot size increases, but in most cases, it can adequately protect the bearing.Increasing size means increasing the ability to withstand eccentricity.

Nowadays, most of the flexible couplings are made of aluminum alloy, of course, there are also stainless steel flexible couplings.In addition to the stainless steel elastic coupling, it also increases the torque bearing capacity and rigidity, and can even reach twice that of similar products made of aluminum alloy.However, this increased torque and rigidity will be offset to some extent by the increased mass and inertia.Sometimes the negative impact will outweigh its advantages, so users have to look for other forms of couplings.

江苏Spiral clutch coupling Shandong spiral clutch coupling

-

How to analyze the cause of damage to the elastic pin coupling?And the classification of elastic pin couplingsElastic pin coupling, generally elastic pin coupling, nylon rod pin coupling, the former is...Take you to understand commonly used elastic couplingsCommonly used elastic couplings are divided into two types of elastic sleeve pin couplings and elastic pin couplings...

-

Rigid movable couplingTypes of rigid removable couplings (couplings without elastic elements): Oldham...Classification and performance of couplingsCouplings are also called couplings.Used to firmly connect the driving shaft and the driven shaft in different mechanisms...

-

The characteristics and maintenance methods of gear couplingGear coupling is a kind of removable rigid coupling.It uses internal and external tooth meshing to realize the torque rotation and movement transmission between the two halves of the coupling. It is suitable for the transmission shaft system connecting two concentric shafts, and has the performance of relatively compensating the relative displacement of the two shafts.Its structure is shown in Figure XNUMX. It is composed of main parts such as inner gear ring, gear shaft sleeve and end cover. Generally, small-sized gear coupling end cover and inner gear ring can be integrated. ...The structure and application range of slider couplingThe slider coupling is also known as the metal cross slider coupling. Its slider is in the shape of a ring and is made of steel or alloy. The cross slider coupling is suitable for transmissions with low speed and large transmission torque.The slider coupling is composed of two shaft sleeves and a slider. ...