How to solve the error and precautions of plum blossom elastic coupling

How to solve the error and precautions of plum blossom elastic coupling

If there is a coupling error, you need to re-align or re-align the reducer side, or re-align the reel side.First find out the part with larger offset error. This is to first measure which side of the coupling is offset, that is, measure the levelness and coaxiality of the main shaft and the level and coaxiality of the reducer main shaft, and then press the quality again. If the scale is copied and leveled, it can malfunction.

Go directly to the topic, how to solve the error and precautions of plum elastic coupling

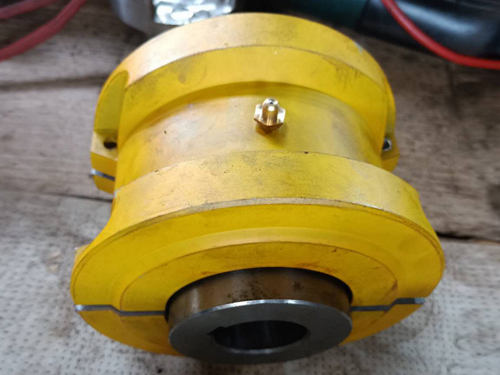

There are three kinds of shaft deviation: one is radial deviation, that is, the two shafts are parallel but the lines are no longer on the same straight line. The deviation generated at this time is called radial deviation; the other is angular deviation, that is, the two shafts are at an angle to each other. The deviation produced; the third type is the axial deviation, that is, the deviation caused by the reciprocating micro-motion of the two shafts.Gear coupling

Deviations do not only occur in the assembly of the equipment. Factors such as vibration, thermal expansion, and bearing wear during the working process can cause deviations.Therefore, it is recommended to adjust the axial deviation to less than 1/3.Not only in chemical plants, but also in other rolling mills, 50% to 70% of the transmission equipment damage is caused by the out-of-alignment of the coupling. The direct loss is the cost of replacing spare parts, and the indirect loss is

It is an unplanned shutdown that causes a large downtime profit loss. How to detect the alignment error of the coupling early and take timely measures to avoid the expansion of the loss is a serious concern in chemical plants. Vibration analysis is to predict the misalignment of the coupling. One of the technologies is that it can judge the gradual change trend of the equipment state, but when judging whether a device is in a misaligned state, it needs to have many previous data and examples for reference.

It is also necessary to distinguish whether it is a bearing, lubricating oil, coupling, or a fixed connection problem, so there are limitations.Infrared camera technology can distinguish overheated parts such as bearings, motor housings, couplings, etc. when the equipment is in poor condition, and determine the alignment error of the coupling, combined with other prediction technologies such as vibration analysis , Its effect will be.

If there is a coupling error, you need to re-align or re-align the reducer side, or re-align the reel side.First find out the part with larger offset error. This is to first measure which side of the coupling is offset, that is, measure the levelness and coaxiality of the main shaft and the level and coaxiality of the reducer main shaft, and then press the quality again. If the scale is copied and leveled, it can malfunction.