Detailed instructions for the installation of the star-shaped elastic coupling

Detailed instructions for the installation of the star-shaped elastic coupling

Regulations

(1) Read this manual carefully before installation.

(2) There is a protective cover outside the star-shaped elastic coupling.

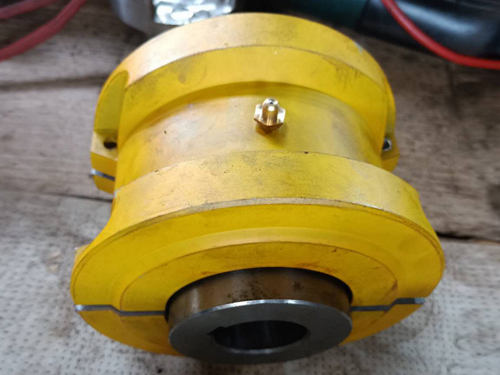

(3) NTA series flexible couplings are made of steel or ductile iron, suitable for left-right rotation and alternating operation.

(4) In order to make the coupling have a longer service life, the concentricity error of the two shafts should be reduced as much as possible during installation, and should not exceed the value required by the machine.

(5) NTA coupling can be used in the temperature range of -30°C—90°C.When used outdoors, avoid direct sunlight, rainwater and other substances that affect the work and service life of the coupling.

(6) NTA couplings are strictly prohibited to be used in liquids.

The adjustment of the star-shaped elastic coupling is very important to the life and smooth operation of the entire connection.The deviation of the axial, radial and angular directions should be less than the displacement value specified by the machine during adjustment. Only in this way can the correcting ability of the coupling in operation be fully exerted.When adjusting, use a ruler, a vernier ruler, and a feeler gauge to check the axial, radial and angular deviations.

Commissioning

After the coupling is installed, perform a trial run according to actual work requirements for no less than ten hours.During the trial operation, observe at any time. If abnormal noise, vibration and other problems occur, stop the machine in time to find out the cause of the problem, and then restart the operation after troubleshooting.Recalculate the time. After the test run, check whether the coupling is normal or not.Is there any mechanical damage on the elastomer?Does the tightening torque of the screws meet the requirements?After confirming that there is no problem, it can be put into normal operation.Star coupling

Maintenance period

In the case of single-shift production, the coupling must be inspected at least once a year (for example, twice for a two-shift system, and three for a three-shift system).If the load is large, the inspection should be more frequent.

装配

To avoid damaging the coupling, please remove the packing box at the assembly site.And check whether the parts are intact, and then clean them before installation.If it is a transition or fit, there must be a positioning surface in the axial direction and lock it with a set screw; if it is an interference fit, the mounting hole needs to be heated, and then installed on the shaft until it is pressed against the shaft shoulder.After the flange, install the elastomer.Fastening screws Use removable anti-loosening glue to prevent loosening.

The elastic body of the star coupling is a vulnerable part. When the coupling is overloaded or over-permitted, it may cause plastic deformation or serious wear of the elastic body. In this case, replace the elastic body.Before replacement, check each part of the coupling. After confirming that it is intact, replace it with a new elastic body, and reinstall and debug it according to the requirements specified in the manual.If you have any questions, please contact our factory.The right of interpretation belongs to the factory.