WGP type drum gear coupling with brake disc

WGP type drum gear coupling with brake disc includes a left sleeve and a right sleeve for connecting the power input shaft and the power output shaft, respectively. Drum teeth are provided at the end of the left sleeve. The connecting sleeve sleeved on the periphery of the left sleeve is meshed with the drum teeth on the left sleeve through its internal teeth. The end of the right sleeve is provided with a connecting flange, and the connecting flange and the connecting sleeve are connected and fixed by connecting bolts. A brake disc is clamped and fixed between the connecting flange and the connecting sleeve.

WGP type drum gear coupling with brake disc has simple structure and easy installation. The brake disc is rigidly connected to the right bushing. The braking load and vibration during braking are borne by the right bushing, so there will be no damage to the drum. The meshing performance of the shaped teeth causes damage, and at the same time the stability of the brake disc itself is also improved, which improves the performance of the operation.

Gear coupling is composed of internal gear ring with the same number of teeth and flange half coupling with external teeth.The external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The center of the spherical surface is on the gear axis. The tooth side is larger than that of ordinary gears. Drum-shaped gear couplings are allowed. Larger angular displacement (compared to spur gear couplings), the contact conditions of the teeth can be improved, the ability to transmit torque is improved, and the service life is prolonged.The contact state along the tooth width when there is angular displacement.

When the drum gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth periodically slide relative to each other in the axial direction, which will inevitably cause tooth surface wear and power consumption. Therefore, the gear coupling needs to be Work in a good and sealed state.Gear couplings have small radial dimensions and large load-bearing capacity. They are often used in shaft transmissions under low-speed and heavy-duty conditions. The dynamically balanced gear couplings can be used for high-speed transmissions, such as gas turbine shaft transmissions.Because the angular compensation of drum-shaped gear couplings is greater than that of straight-tooth couplings, drum-shaped gear couplings are widely used.

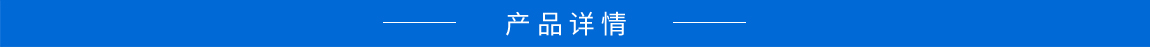

Jiangsu WGP type drum gear coupling with brake disc Shandong WGP type drum gear coupling with brake disc

-

How to analyze the cause of damage to the elastic pin coupling?And the classification of elastic pin couplingsElastic pin coupling, generally elastic pin coupling, nylon rod pin coupling, the former is...Take you to understand commonly used elastic couplingsCommonly used elastic couplings are divided into two types of elastic sleeve pin couplings and elastic pin couplings...

-

Rigid movable couplingTypes of rigid removable couplings (couplings without elastic elements): Oldham...Classification and performance of couplingsCouplings are also called couplings.Used to firmly connect the driving shaft and the driven shaft in different mechanisms...

-

The characteristics and maintenance methods of gear couplingGear coupling is a kind of removable rigid coupling.It uses internal and external tooth meshing to realize the torque rotation and movement transmission between the two halves of the coupling. It is suitable for the transmission shaft system connecting two concentric shafts, and has the performance of relatively compensating the relative displacement of the two shafts.Its structure is shown in Figure XNUMX. It is composed of main parts such as inner gear ring, gear shaft sleeve and end cover. Generally, small-sized gear coupling end cover and inner gear ring can be integrated. ...The structure and application range of slider couplingThe slider coupling is also known as the metal cross slider coupling. Its slider is in the shape of a ring and is made of steel or alloy. The cross slider coupling is suitable for transmissions with low speed and large transmission torque.The slider coupling is composed of two shaft sleeves and a slider. ...