Matters needing attention in coupling maintenance

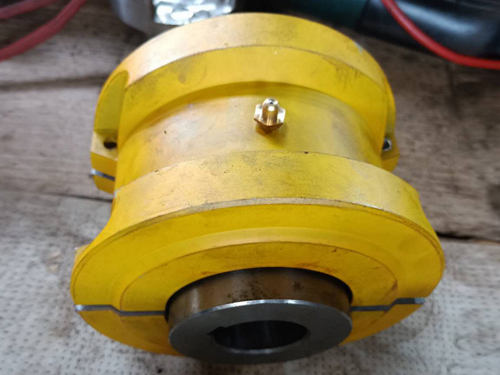

Couplings are mainly used to connect coaxial lines or two parallel shafts to transmit torque.On the crane, the torque of the motor is transmitted to the low-speed shaft through the reducer and the coupling to complete the load lifting, the operation of the large and small vehicles, etc. The gear coupling on the crane is mostly used, and the elastic pin coupling is not commonly used, because Installation accuracy, loose anchor bolts, deformation of bridge frame, poor lubrication and other reasons cause tooth wear.Therefore, the coupling should be checked frequently.

(1) The basic requirements for coupling inspection: the coupling of the coupling must be firm, the connecting bolts and connecting keys must not be loosened, and the radial and end face of the rotating coupling should not be obvious during visual observation. Feel, measure with a meter.

(2) Inspection of the gear coupling: When the gear coupling has increased transmission noise or the equipment is overhauled, it should be disassembled and inspected, and the following items should be checked:

① When the coupling bolt holes are worn severely, the mechanism will jump when the mechanism is started, and the bolts will even be cut off. Therefore, the bolt holes should be scrapped if they are severely worn and cannot be used.

② When the tooth thickness wear exceeds 15%-20% of the original tooth thickness, it should be scrapped.Lifting mechanism and unbalanced luffing mechanism are 15%, and other mechanisms are 20%.

③After the flat keyway is worn out, the key is easy to loosen or even fall off.You can reopen a new keyway at the position where the original keyway on the shaft has been rotated 90° or 180°, or add a pad that does not exceed 15% of the pad thickness on the key.Repair welding of the keyway is not allowed, and repairing of the keyway of the lifting mechanism is not allowed.

④ If any part of the coupling has cracks, it should be scrapped, and if there are broken teeth, it should be scrapped.

(3) Inspection of the elastic coupling: When the rubber ring or cowhide pad of the elastic pin coupling is damaged, it should be replaced in time. If the pin and hole are squeezed to cause vibration, the half body should be rotated by an angle and re-drilled. The hole is replaced with a new standard pin, and the original hole is not allowed to be enlarged and replaced with a new pin.

(4) Whether the coupling oil seal with lubrication device is intact, whether the lubricating oil is deteriorated, whether there is oil leakage or oil leakage.If the above problems occur, the seal or lubricating oil should be replaced. If the lubricating oil is lacking, it should be refilled in time.

Next:Installation and maintenance of coupling