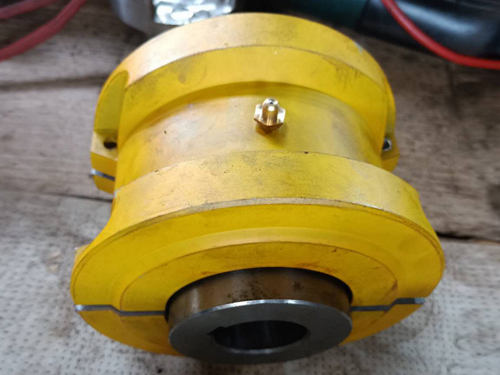

Use and maintenance of coupling

Coupling is the intermediate connecting part of each motion mechanism, it has a direct impact on the normal operation of each motion mechanism, so please pay attention to:

① The coupling is not allowed to have more than the specified shaft center line skew and radial displacement, so as not to affect its transmission performance.

② The bolts must not be loose or damaged.

③Gear couplings and Oldham couplings should be lubricated regularly, and grease should be added once every 2 to 3 months to avoid severe wear of gear teeth and serious consequences.

④The contact length of gear coupling tooth width shall not be less than 70%, and its axial movement shall not be greater than 5mm.

⑤The coupling is not allowed to have cracks, if there is a crack, it needs to be replaced (it can be knocked with a small hammer, judged by the sound).

⑥The key of the coupling should be tightly matched and not loose.

⑦ The tooth thickness of the gear coupling is worn out. When the lifting mechanism exceeds 15% of the original tooth thickness, when the operating mechanism exceeds 25%, it should be scrapped. If there is a broken tooth, it should also be scrapped.

⑧ If the elastic ring of the pin coupling and the sealing ring of the gear coupling are damaged and aging, please pay attention to timely replacement.

The installation error of the coupling should be strictly controlled. Generally, the installation error should not be greater than 1/2 of the allowable compensation amount.

Pay attention to check the alignment of the two connected shafts after operation, and the relative displacement should not be greater than the allowable compensation amount.Reduce the relative displacement as much as possible, which can prolong the service life of the connected machinery or coupling.

For couplings that require lubrication, such as gear couplings, the amount, quality, and sealing condition of the lubricating oil should be checked regularly, and should be supplemented or replaced.

For couplings on high-speed rotating machinery, it is generally required to undergo a dynamic balance test and assemble according to the marks.The weight difference between its connecting bolts is strictly restricted and shall not be exchanged arbitrarily.

Next:Performance and characteristics of plum elastic coupling